Anatomy of Craftsmanship: The Journey of Our Bespoke Brass Handles

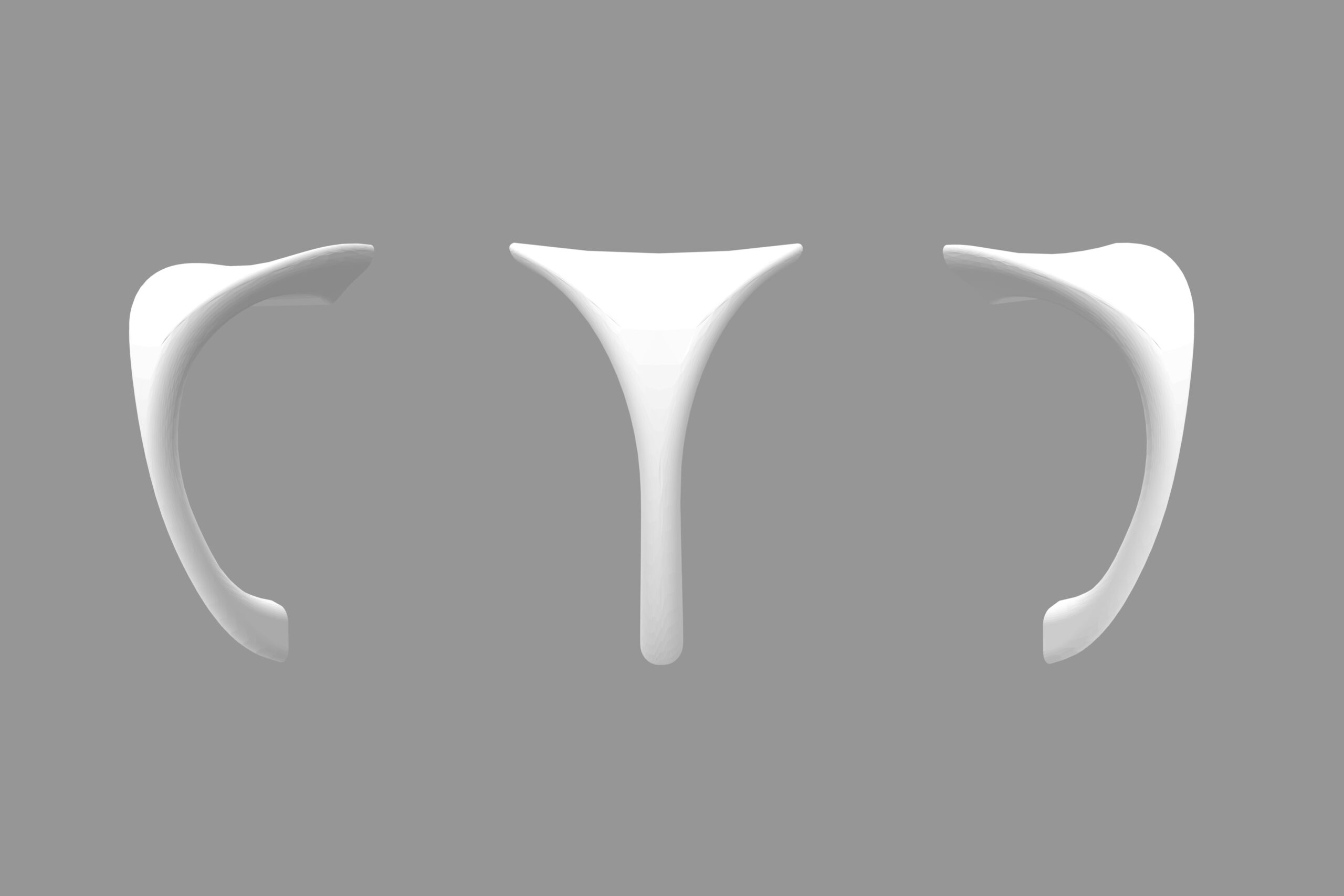

The process of creating our bespoke brass handles combines modern techniques with traditional craftsmanship. It begins with a thorough design phase, where sketches are created and refined to ensure the design meets both aesthetic and functional requirements. Once the design is finalised, it is transferred to the digital domain, where a precise 3D printed model of the handle is crafted. This model captures every detail with accuracy and serves as the foundation for creating the mould that shapes the rest of the process.

Lost Wax Casting

From the mould, we create a wax replica using the lost wax casting method – a technique with a long history, thought to date back over 5,000 years. This method has been used across cultures, from ancient Mesopotamia to traditional Chinese and Indian metalwork, because of its ability to produce highly detailed and intricate designs. It was later adopted in Europe during the Renaissance for creating fine sculptures and jewellery.

The wax replica is coated in Investment, a specialised material that hardens into a strong, heat-resistant shell. After curing, the wax is melted out, leaving behind a hollow mould. Molten brass is poured into this cavity, capturing every detail of the original design. Once cooled and solidified, the Investment shell is broken away, revealing the rough brass casting.

Refining & Polishing

Following this, the handle undergoes a refining process in the Polishing department. Imperfections are meticulously removed and surfaces smoothed, preparing the handle for its finishing touches. Once refined, the handle is passed to the Finishing department. Here, it is cleaned thoroughly in specialist tanks to ensure it is pristine and ready for its final finish.

Finishing & Fitting

The finishing process can vary depending on the client’s preferences. Options include antiquing, silver plating, or other bespoke finishes chosen from our in-house library. This thoughtful process, combining cutting-edge technology with centuries-old craftsmanship, ensures every Morris Bespoke handle is as unique and exquisite as the furniture it adorns.

We hope this behind-the-scenes look at the craftsmanship involved in our bespoke brass handles has offered an engaging glimpse into our process. If you’re inspired by the possibilities of bespoke design, we invite you to explore the Morris Bespoke Collection – a showcase of our contemporary and timeless, handcrafted furniture. Whether you’re looking for something unique or wish to bring your vision to life, our team is here to help. Please do get in touch to discuss your project or to learn more about how we can create something truly special for you.